27 – 31 March 2023

See you at the PLÁSTICO BRASIL, São Paulo Expo pavilion!

There are more than 800 national and international exhibition brands which present their products and launches in a space of more than 40,000 m².

Plastico Brasil is a true business platform that provides new opportunities for exhibitors and visitors.

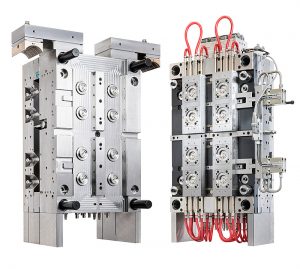

Another special development of HTW molds – Made in Austria.

We have created a completely new product for a customer and also reinvented the self-closing unit especially for this new cap design.

- 16 cavities

- cycle times of 10-12 seconds

- self-closing unit

The whole project was a collaboration of Engel Austria GmbH with Kadbanno.

For any further requests, please contact us at any time:

sales@htw-werkzeugbau.com

High precision silicon and grease cartridge molds!

NEW! Available at htw!

More than 30 years of experience and Know-How have gone into the development of this new product segment, which we have already incorporated into mold construction for high-quality closures.

The new cartridge molds are characterised by better filling and quality in comparison to standard molds on the market. The valve gate system completes an all-round perfect mold construction.

Silicon cartridges

- 2, 4, 6, 8, 12, 16 cavities

- Cycle time 10-12 seconds

- Valve gate for better filling and better quality

Grease cartridges

- 2, 4, 6,8 cavities

- Cycle time 12-14 seconds

- Valve gate for better filling and better quality

Cap Mold Engineering ahead of its time

We focus on our costumers‘ requirements and rely on our long-term experience, in order to design the best possible solution. Therefore, we apply state-of-the-art design and machinery.

htw will provide you with extensive expertise to develop the best possible product solution. If required a pilot mold with reduced number of cavities can be produced within a short time for testing purposes. The knowledge gained through testing in pilot molds can be transferred to the commercial mold. The pilot mold as well as all commercial molds can be tested in our in-house testing center.

In order to ensure a top performance of the molds even in extreme conditions (e.g. low cycle times), we pay close attention to processing parameters and material selection.

Facts

Molds in Action

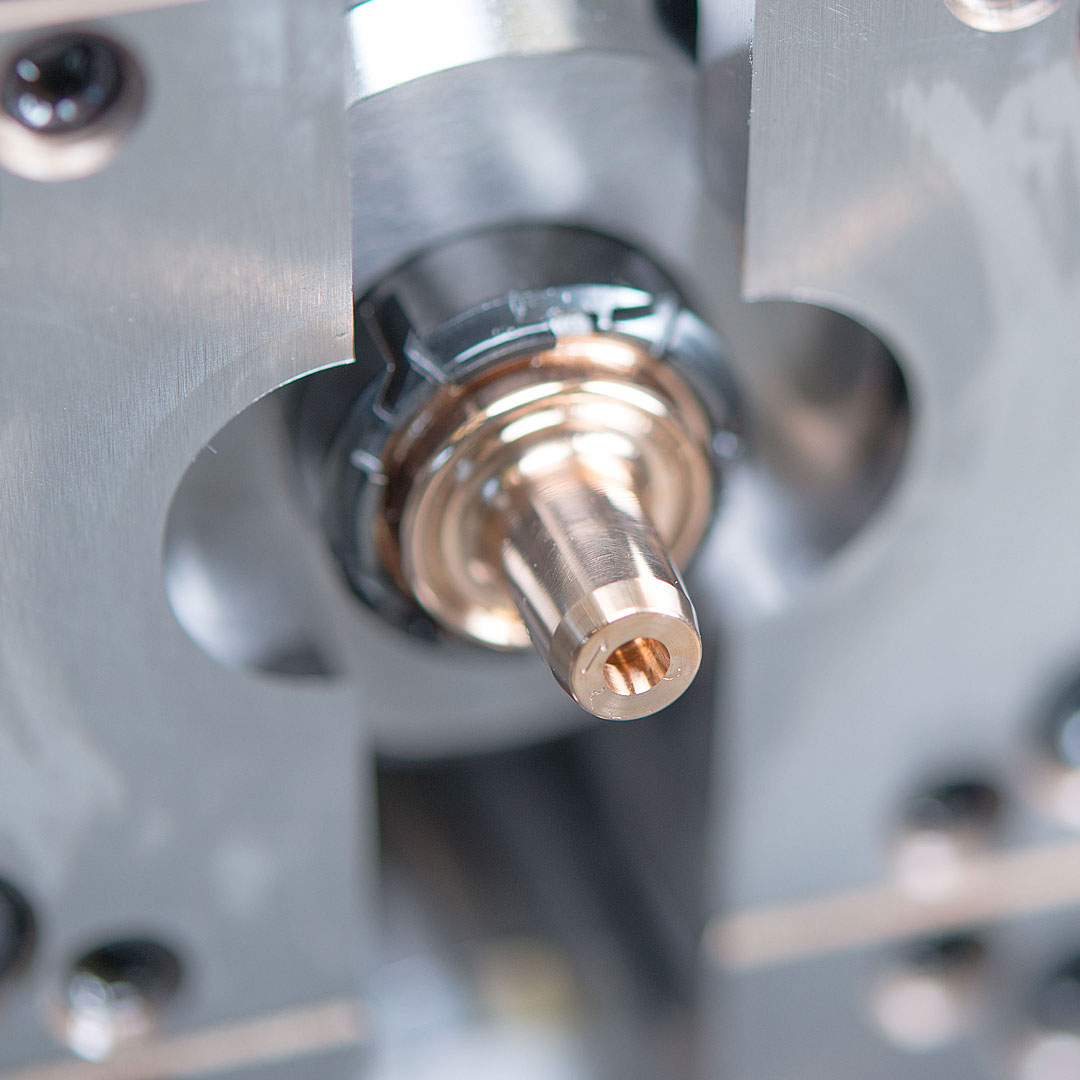

Toolstar Hotrunner System

- nozzle tip cleaning directly on the machine

- competitive prices

- independent spare parts management

- high class after sales service

- worldwide service